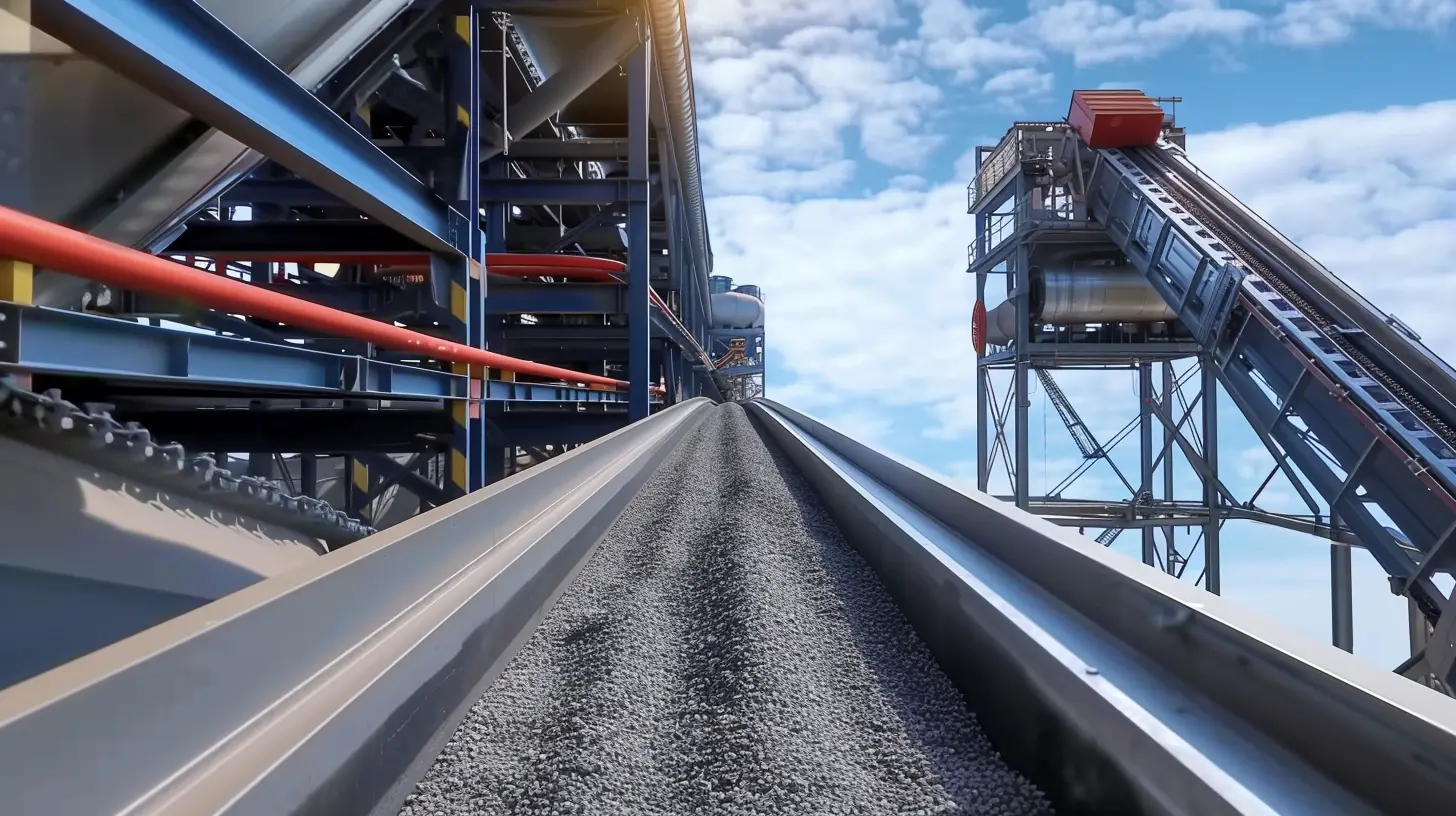

The inclined chain conveyor is a key piece of equipment in modern logistics systems and is designed to improve the efficiency of material handling. Its unique inclined structure makes material transportation in the vertical direction more efficient, especially suitable for multi-layer warehousing and production sites.

Through the application of inclined chain plate conveyors, companies can significantly increase the logistics speed of production lines. This not only reduces the movement time of materials in the workshop, but also improves the overall operating efficiency and brings higher productivity to the company.

Due to the flexibility of the inclined chain plate conveyor, it can be customized according to the actual layout of the workshop. This design enables the logistics link to be seamlessly integrated with the production process, thereby making more rational use of space and reducing the waste of manpower and material resources.

The automated operation of the inclined chain plate conveyor can effectively reduce manual intervention and reduce labor costs. At the same time, its design also takes safety into consideration, improving the safety of the working environment by reducing manual handling of materials.

According to customer feedback, after a large manufacturing company implemented an inclined chain plate conveyor, the material transportation efficiency increased by 30%, and the safety of workers' operations was also significantly improved. Successful implementation cases prove the actual effect of this equipment in improving logistics efficiency.

As an advanced logistics automation solution, the inclined chain plate conveyor plays an important role in improving conveying efficiency, optimizing workshop layout and reducing labor costs with its unique design and significant advantages. By choosing an inclined chain plate conveyor, you will start a revolution in logistics efficiency.

.jpg)