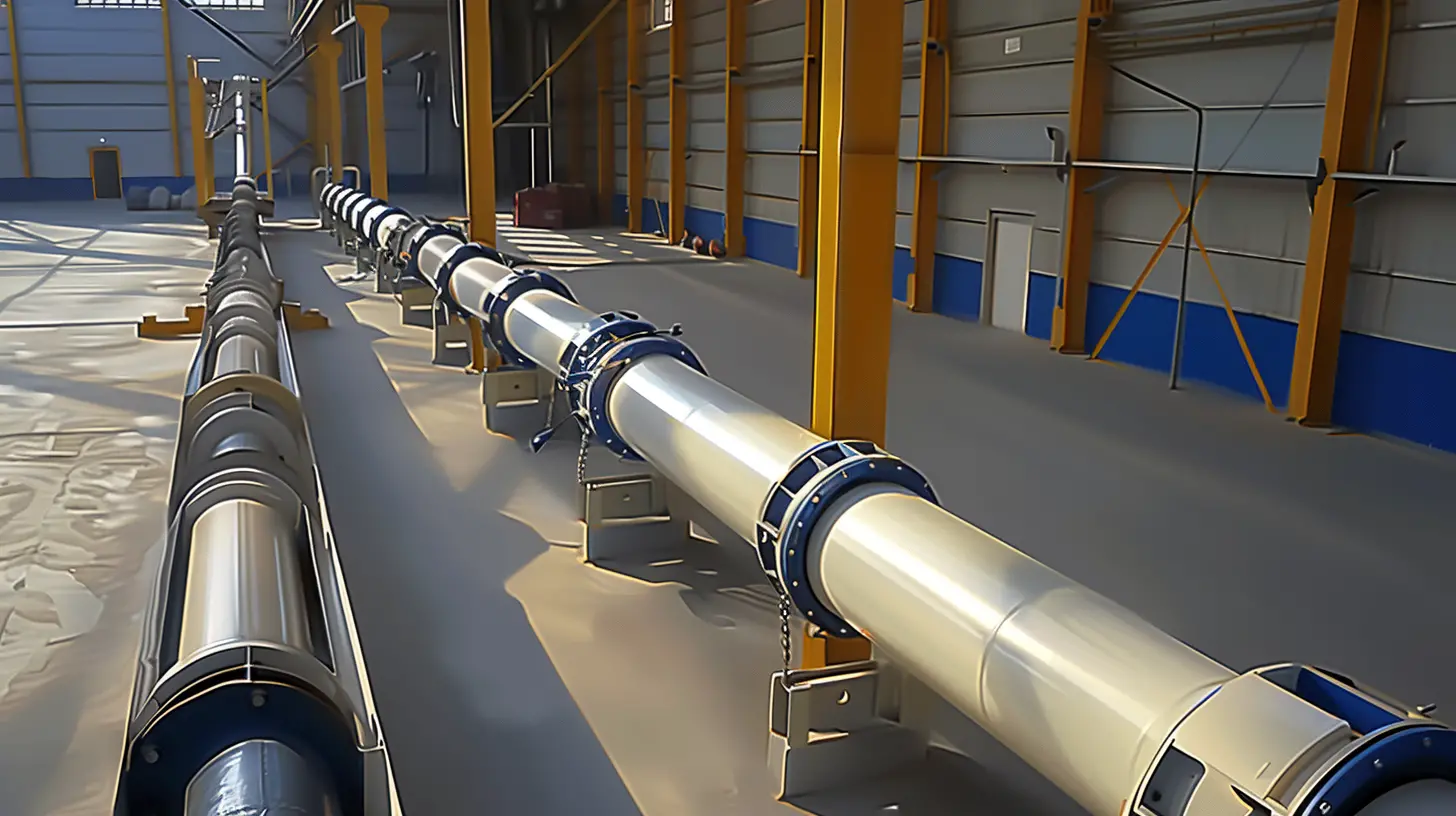

Industrial conveyors play a vital role in the manufacturing and logistics industries, and their service life is directly related to the operational efficiency and cost control of enterprises. In this article, we will explore in detail the various factors that affect the service life of industrial conveyors, and how to extend their service life through reasonable maintenance and optimized design.

The service life of industrial conveyors is affected by several factors, including:

Equipment maintenance can be divided into routine maintenance and periodic overhaul. Routine maintenance includes cleaning and lubrication, while periodic overhaul focuses on the inspection and replacement of key components. Through a reasonable maintenance strategy, enterprises can reduce downtime and improve production efficiency.

In the design stage, the integration of advanced technologies and materials, such as highly wear-resistant conveyor belts and high-strength brackets, can effectively improve the production efficiency and service life of the equipment. Design optimization can not only improve the stability and safety of the conveying process, but also reduce energy consumption and optimize the overall operating costs.

The service life of industrial conveyors is closely related to multiple factors. Enterprises need to attach great importance to equipment maintenance and design optimization. Through reasonable strategies, enterprises can not only extend the service life of equipment, but also effectively improve overall production efficiency, laying a solid foundation for future sustainable growth.