The handling of non-stick materials in the pharmaceutical industry has always been a challenge in the production process. Effective material transportation not only affects production efficiency, but also involves production safety and environmental protection. Therefore, it is particularly important to explore efficient transportation methods.

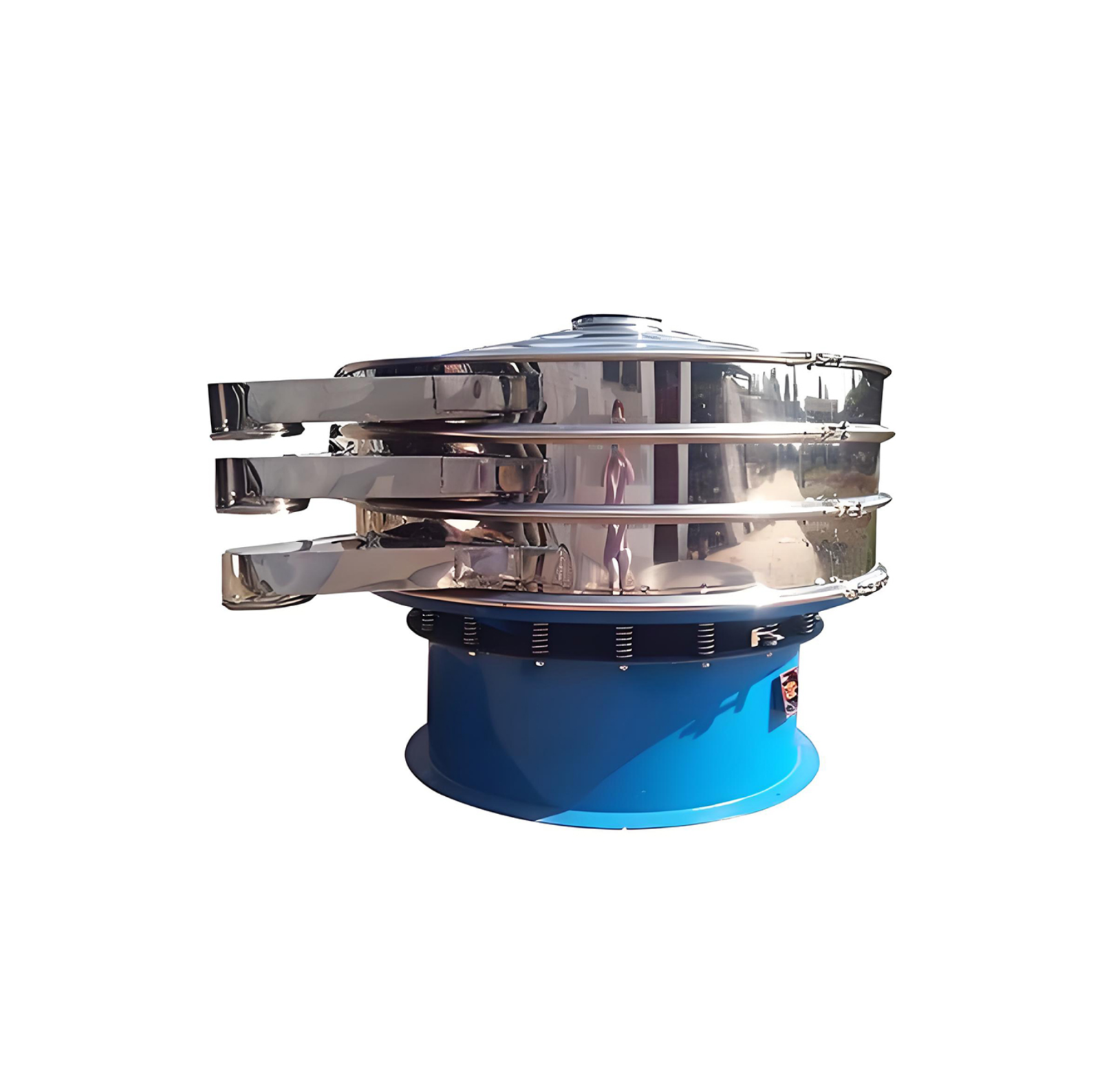

When choosing conveying equipment for non-stick materials, we can consider the following equipment: rotary vibrating screens and linear vibrating screens. These devices can effectively reduce the adhesion of materials during the conveying process.

A reasonable conveying path is an important factor in ensuring the smooth conveying of non-stick materials. By reducing equipment turns and improving the straightness of conveying, the loss of materials during conveying can be effectively reduced. At the same time, when designing the conveying path, it should be ensured that all conveying sections can be easily cleaned to improve hygiene standards.

Appropriate material coating on the surface of conveying equipment can effectively reduce the probability of material adhesion. For example, equipment coated with polytetrafluoroethylene (PTEF) material can significantly improve the fluidity of materials. At the same time, the wear resistance of the coating also helps extend the service life of the equipment.

In today's Industry 4.0 era, automation solutions have become the key to improving production stability and safety. In the conveying process, the intelligent conveying system can monitor the status of materials in real time and automatically adjust the conveying speed and direction, thereby improving overall production efficiency.

The efficient conveying methods introduced in this article, whether through reasonable selection of conveying equipment, optimization of conveying paths, or selection of appropriate coating materials, all point to one goal: achieving cost savings and improving efficiency. We hope this guide can provide pharmaceutical companies with a practical reference to help achieve more efficient material management and production goals.