In today's fiercely competitive market, bucket elevators are an important material handling equipment, and their service life directly affects an enterprise's production efficiency and cost control. After years of practice and research, we have summarized the following methods to extend the service life of bucket elevators to help you better maintain your equipment.

Regular inspection and maintenance of the bucket elevator is the first condition to ensure the normal operation of the equipment and extend its service life. Inspections include:

-Looseness of equipment connection parts;

- The degree of wear on the motor and transmission system;

- Integrity of various seals.

Proper lubrication can not only reduce friction and reduce equipment wear, but also prevent rust. We recommend using lubricants recommended by the manufacturer, lubrication of various moving parts on time, and keeping the lubrication system clean.

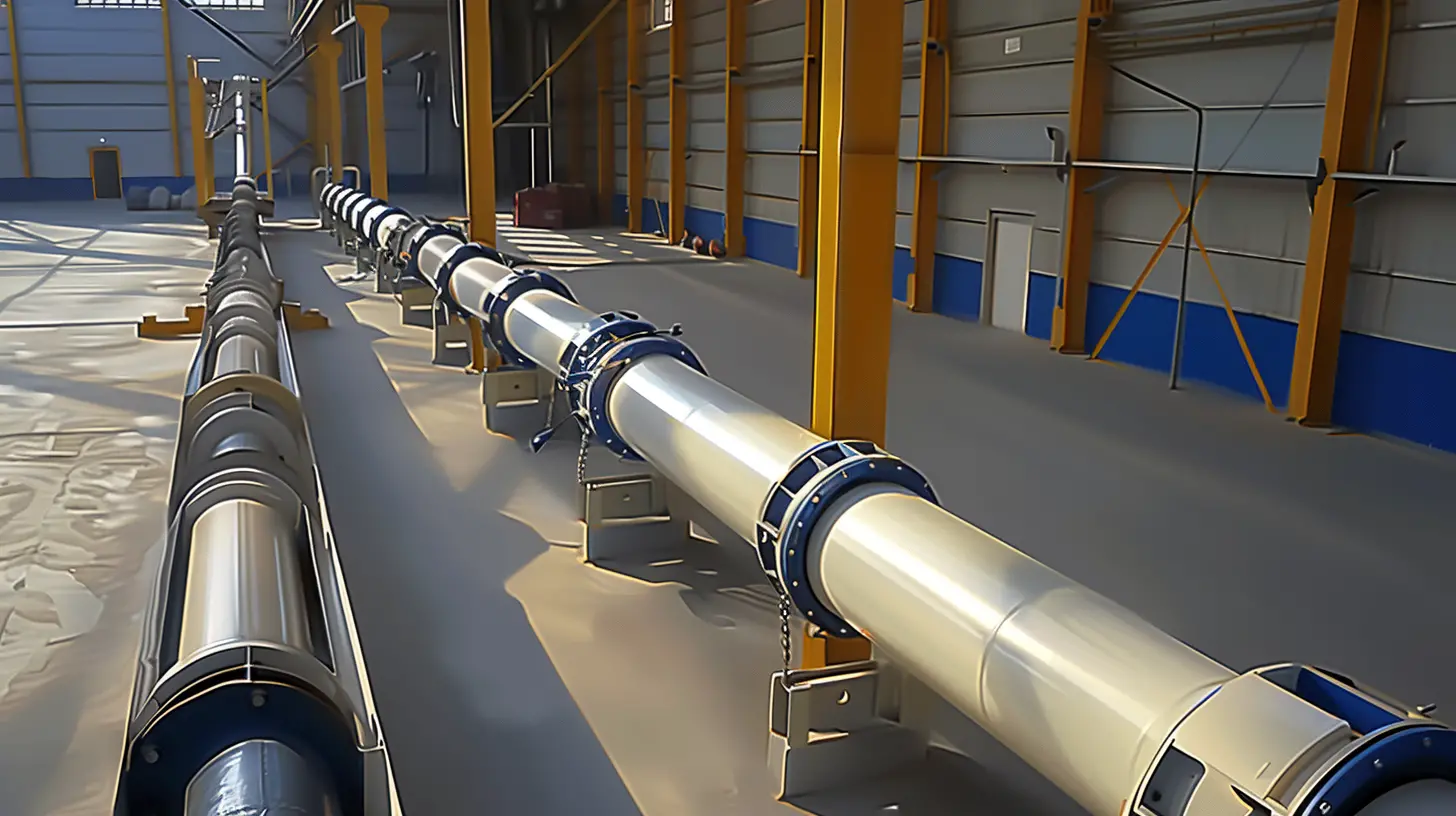

The materials used in the design and operation of a bucket elevator directly affect its durability and wear resistance. Ensuring that you choose high-quality materials that meet the requirements of your equipment can significantly increase the service life of your bucket elevator.

The operating environment of the bucket elevator will also affect its service life. Avoid working in high humidity, high temperatures, or corrosive environments to reduce the risk of equipment damage.

Regular training for operating employees to understand the correct operation and maintenance methods of equipment can effectively reduce equipment failures caused by improper operation.

Through the efforts in the above aspects, you will be able to significantly extend the service life of the bucket elevator, improve the efficiency and safety of the equipment, and thereby create greater value for your enterprise. If you need further professional advice or equipment maintenance services, please feel free to contact us and we will be happy to serve you!