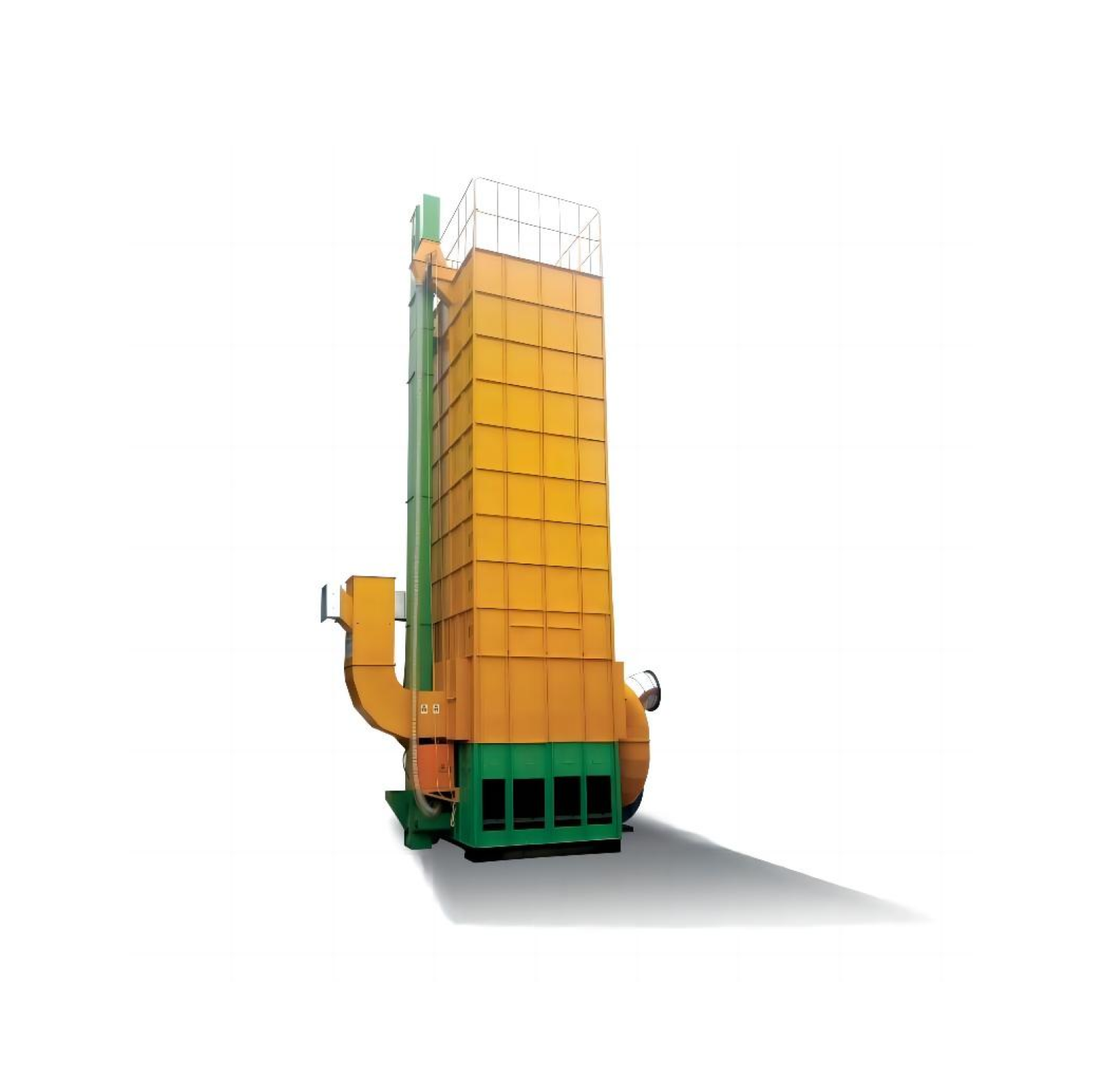

In agricultural production, the grain drying process is a very critical link. As a modern agricultural equipment, grain dryers can effectively remove moisture from crops and ensure the quality and storage safety of grain. This article will start from the working principle of grain dryers and deeply explore their important impact on improving grain processing efficiency.

Grain dryers mainly achieve the drying process of grains through hot air circulation and moisture discharge. Its working principle can be divided into the following steps:

Hot air circulation is the core technology of grain dryers. The heated air is evenly sent into the drying chamber through the hot air blower, and fully exchanges heat with the grain to be dried, so that the moisture evaporates quickly. The hot air circulates in the drying chamber, which can effectively improve the heat utilization rate and speed up the drying process.

During the hot air circulation process, moisture will be continuously released as the water evaporates. The grain dryer is equipped with an efficient dehumidification system that can quickly discharge moisture and maintain a dry environment in the drying room. This process ensures that the grain maintains higher quality and storage safety in a dry state.

The use of grain dryers has a significant impact on the quality and storage safety of crops. First, it can effectively control the moisture content of grains, reduce mildew and pests caused by improper storage, and thus improve the storage safety of grains. Second, the appropriate drying process can retain the nutrients in the grains and improve their market competitiveness.

As a modern agricultural equipment, grain dryer plays a vital role in improving grain processing efficiency and ensuring agricultural production. Understanding its working principle and application will help farmers and grain processing companies to better utilize this equipment and achieve efficient and safe grain storage.