In modern industry, conveying equipment has become an important tool for improving production efficiency and optimizing logistics processes. By analyzing application cases in different fields, we can deeply understand how these devices play a key role in improving efficiency, reducing costs and promoting automation.

Conveying equipment can be widely used in many industries, including food processing, construction, manufacturing, etc. Here are some specific application cases:

In the food processing industry, conveying equipment can effectively move raw materials and finished products. For example, chain conveyors can be used to move food from one process to another on the production line, ensuring the continuity and efficiency of the production process.

Construction sites need to transport a large amount of raw materials from one place to another. The use of conveyor belts can improve logistics efficiency and reduce labor costs. Especially in large projects, the use of mobile conveying equipment can quickly and safely complete the transportation of materials.

In the manufacturing industry, the efficient operation of assembly lines is crucial to the production efficiency of enterprises. By adopting automated conveying systems, such as roller conveyors, fast transportation and precise docking of parts can be achieved, thereby optimizing the production process.

In this section, we will analyze several successful cases in specific industries and how they have achieved improved logistics efficiency through the use of conveying equipment:

In a large food processing enterprise, a fully automated conveying system was introduced, which significantly reduced the time of manual handling and increased production efficiency by 30%. The combination of chain conveyors and belt conveyors greatly improved the safety and sanitation of food.

A construction company used a mobile conveyor on a major project to quickly transport concrete and sand and gravel, significantly shortening the construction period. Due to the high efficiency of the equipment, construction costs were reduced by 15%.

During the automobile manufacturing process, a highly automated production line is adopted, and a roller conveyor system is used to reduce the time that parts are stationary, thereby increasing the efficiency of the entire automobile assembly process by 20%.

Through the analysis of these application cases, we can see that conveying equipment plays an indispensable role in various industries. Enterprises should choose appropriate conveying equipment according to their own production characteristics and logistics needs to improve efficiency, reduce costs, and ultimately achieve business growth.

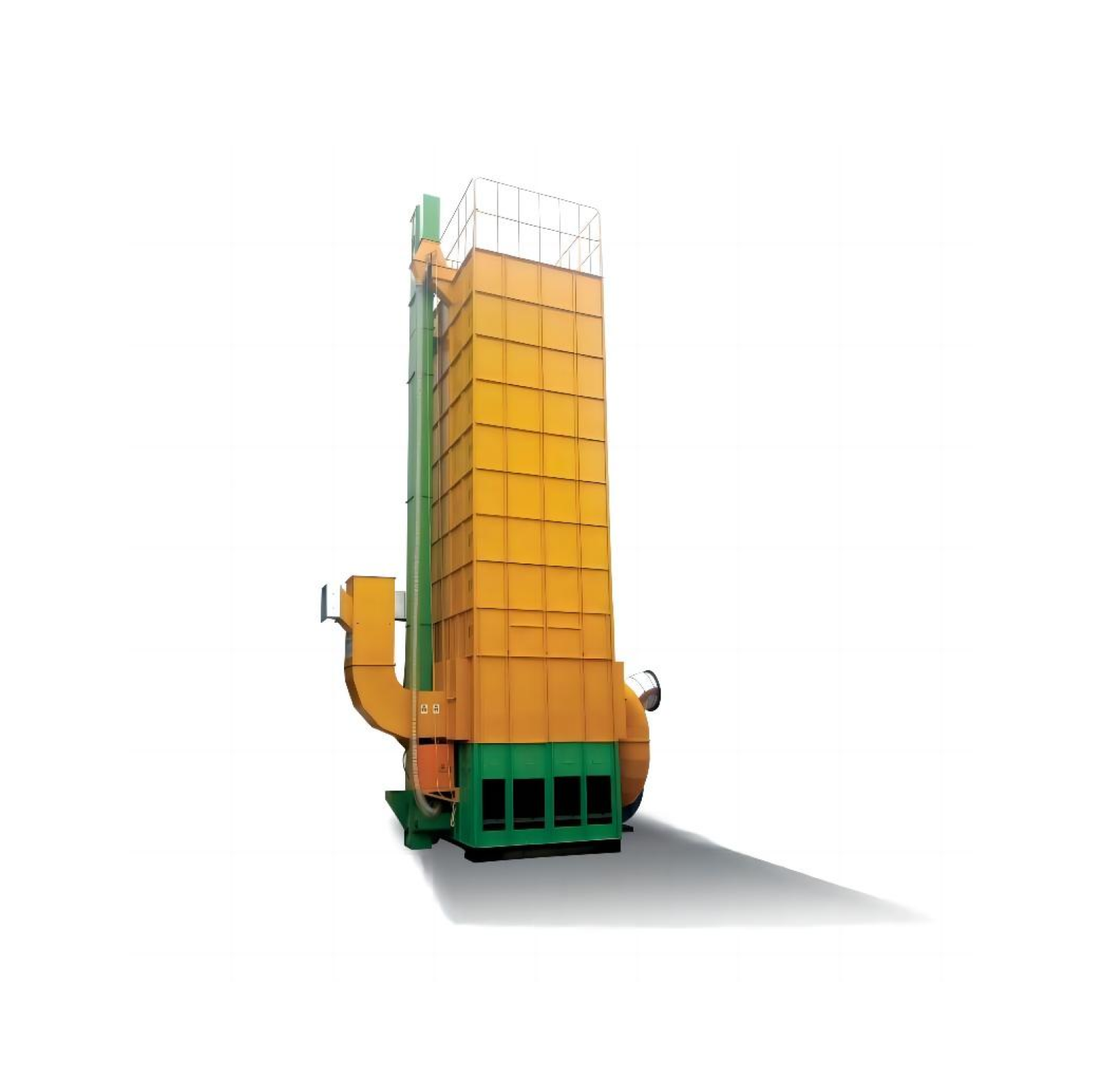

Grain dryer

Industrial Dryer